Chargecooler

The Esprit's Intercooler, cooler the air from the turbo for more powerFour cylinder models (SE, S4, S4s & GT3) use an air/water heat exchanger (chargecooler) to reduce the temperature and increase the density of air leaving the turbocharger compressor before it enters the intake plenum chamber. The chargecooler is flexibly mounted to the engine, and uses flexible high temperature hoses to connect the intake and outlet to the compressor and plenum respectively. Air passing through the chargecooler flows past a matrix of tubes through which water is circulated in a closed system by an engine driven pump. Heat is transferred from the intake charge air to the water which is pumped via alloy pipes routed through the chassis backbone, to a chargecooler radiator mounted ahead of both the air conditioning condenser and the engine cooling radiator.

On air conditioned cars pior to March ‘95 using refrigerant R12, the a.c. condenser and chargecooler radiator are constructed as one unit with integral side frames. Later cars using refrigerant R134a use a pair of ‘ side by side’ condensers, and a separate chargecooler radiator.

On Sport 300 models without air conditioning, the RI2 type of integrated a.c. condenser is adapted to become a second chargecooler radiator in addition to the standard item ahead of it, with the plumbing arranged to provide parallel water flow through the two radiators.

Prior to December ‘93, the chargecooler system is entirely separate from the engine cooling system, and is equipped with its own header tank mounted adjacent to the engine header tank at the left hand rear corner of the engine bay. The tank, which should be filled (cold) to a level 25mm below the filler neck, is connected into the chargecooler pump inlet hose, and is fitted with a 48 kPa (7 psi) pressure cap. From December ‘93, the chargecooler system, whilst continuing to function in a largely independent manner, is linked with the engine cooling system by a connection between the chargecooler air bleed spigot and the engine coolant header tank, thus dispensing with the need for a separate chargecooler tank.

The chargecooler pump is driven off the rear end of the auxiliary shaft in the position occupied on some earlier engine variants by the ignition distributor, and uses an impellor with flexible vanes mounted in an eccentric chamber.

Plumbing for 160mph (260kph): the mid-motor Esprit SE needed the services of an

automotive plumber to provide the services listed in this 1989 factory diagram.More Power

Mechanical changes over the Giugiaro 910S (HC) turbo 2.2-litre were comparatively confined, yet horsepower grew by 14 per cent and torque by 17 per cent. That extra pulling power was achieved at 1,000rpm less than the previous European turbo Esprit. Most of that extra power - the engine is capable of holding a transient 280bhp for periods of up to 30 seconds, and an almost unmatched production 121.5bhp a litre is routinely achieved - can be attributed to the use of a compact Behr intercooler. This runs an unspecified 'cooling liquid' mixture around a separate layout that features its own header tank and forward radiator; its plumbing runs forward and aft within the chassis, just like any number of sixties and seventies racing cars.It is this small liquid-filled cooler that is dubbed the chargecooler'. Conventional inter-coolers are air-to-air radiators that require a lot more space, and create unwanted extra aerodynamic drag. A Jabsco pump drives the chargecooling liquid system, taking power up from the old distributor slot. Reduced intake temperatures that Lotus claim for the system, operating in a warmish 4oF (200C) ambient are: 238oF (1500C) into the charge-cooler and 76oF (600C) outward bound, ready for induction delivery.

The fuel injection system was based on components from the GM-Rochester division, but also featured two supplementary injectors to the primary four, all by Multec. The secondary injection pair operate within the plenum chamber to meet maximum power demand conditions. This is a sophisticated alternative to the common fifth (four-cylinder) or seventh (six-cylinder) injector found in many UK aftermarket turbo systems.

The first Esprit to run any kind of intercooling device. the SE featured such a compact

yet effective system that its Behr heart was also featured on the subsequent

twin turbo Lotus Vauxhall/Opel Carlton/Omega saloons.The engine changes included chrome-plated crowns to forged Mahle 8:1 compression ratio pistons and detail induction and exhaust work. We equalised the tract lengths to reach that of the shortest distance between exhaust valve and turbocharger entry, finding that turbo-charged engines are not so sensitive to exhaust manifold changes at this point. We reduced exhaust manifold system weight significantly (up to 30 per cent) by analysis of the iron castings that we had been using and the substitution of more advanced material mixes.

At the HC Esprit stage, we had introduced the integral waste-gate as part of a new Garrett AiResearch TB03 fitment, which also allowed us the use of water-cooling in the central casing. In itself, this prevents the kind of oil ęcoking deposits that had been a problem for Saab and ourselves in earlier turbo installations.

Under Pressure

On the sensitive question of maximum boost pressures, Lotus had their electronic management hold a cold-start figure of 0.65 bar/9.4psi and a warmed pressure of 0.85 bar/12.4psi for the SE. Rapid acceleration at less than 3,000rpm is allowed a degree of over-boost upon this figure (how much more was not specified, but I was told by Lotus that 'the high boost condition is available only for short duration to provide initial vehicle acceleration').For comparative purposes, the original turbo ran a maximum of 8psi, whilst the GMP4 American emission specification, non-intercooled predecessor to the SE held l2psi to 3,000rpm and then dropped back to a constant commitment of 10psi.

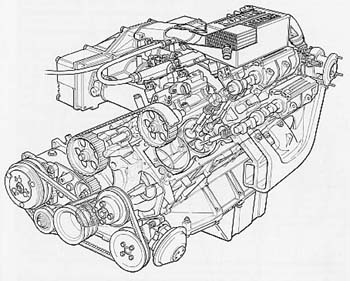

Contrast this Mark Roberts cut-a way of the Lotus 9105 Chargecooled turbo with the

original dry-sump and non-intercooled unit and you will see that the basic engine principles remained,

but that the ancillarie s commanding turbocharger performance were radically altered.There were some dimensional changes to the aluminium-block liners because the material strengths were altered, but there was also an extra boss to insert on one cylinder to install the knock control sensor. We drilled holes all over the place to get the optimum position for this sensor, but it has been worthwhile as the boost and ignition settings can be more precisely set without harming durability.

The exhaust system was new from the manifolds down and lowered back pressure was our design priority here, along with a lot of work from Southampton University and ourselves to lower noise and vibration levels in this area.

On the inlet side, longer tracts than previously used on the turbo showed an improvement in low-speed torque than we had seen on normally-aspirated engines. For the turbo, it also meant a better transition in power characteristics when boost was building up.

Chargecooler info

from the factory at HethelLotus have been reading LEW's news page and have asked me to list the following as an explanation of the service details for the chargecooler pump. This text is taken from the workshop manual. Don't panic, LEW's not in trouble!

On chargecooler equipped vehicles where maximum performance is a priority, it is recommended that the chargecooler water pump impeller is inspected at 18,000 mile (30,000 km) intervals, and replaced if necessary to ensure optimum efficiency of the charge air cooling system. This inspection is for performance reasons only, as the condition of the impeller has no adverse affect on driveability or emissions. (Part No. B910E6922F)

The chargecooler version of the Esprit was developed during 1988 so the technology is now about 15 years old. The pump impeller material has been updated when an improved rubber composition became available. This is an important issue as if owners source the impeller from a non Lotus source (this impeller is used in many non automotive applications) they may not get the updated version as supplied by Lotus Aftersales.

Chargecooler Statement

I have noticed several comments on the net following the latest chargecooler statement. The reason for publishing this is to remind owners that the Lotus Service Notes identify this item as requiring regular inspection / maintenance. From our testing (both dyno and vehicle) we know that there is a gradual degradation of the impeller over time / mileage. The reason for the 18,000 mile inspection / maintenance is to ensure that the component is 'viewed' before it gets to a point of failure (broken vanes).From test results the working life of the component is well in excess of 18,000 miles of normal vehicle use. Any prolonged periods of inactivity or increased heat can reduce the working life of the component. As the component efficiency normally drops off very gradually (unlikely to be noticed initially by the driver) we have recommended that this component is inspected / changed if necessary before it degrades to a condition that can have an influence over the operation of the engine management system and then to the attention of the driver.

We know that many owners do not realise that they are driving a car with a chargecooler system that has lost some or all of it's efficiency – the statement in the Service Notes is there to guide owners to get the best out of their car – nothing sinister is intended.

Chargecooler Pump body's and covers

LEW has today heard that the tooling to produce the Chargecooler pump body and end cover is no longer available (supplier in liquidation) but Lotus have confirmed that their supplier will still be able to provide all the other components for the pump. Lotus plan is to put together a kit of parts that will enable the existing pumps to be overhauled with the original parts. It is unlikely that the pump body will need replacing in the life of the car. Every other part needed to service the pump and bring it up to 'as new' condition will be available. Lotus are also looking into the electric pump option as an alternative, with their main concern being a stable & safe power supply for the pump.Now this is sad news, as it seems original Esprit parts are going to become harder and harder to get hold of. Luckily this particular part shortage shouldn't be a problem, as with the gearboxes, Lotus can recon them to keep cars on the road. Hopefully Electric pumps will put an end to the need for the old type of pump in the near future.

Chargecooler impellers

If you've got an SE through to a GT3, then you've got a chargecooler, which means you'll have a chargecooler pump, which pushes the water around the system, which in turn, cools the charge. The impeller, which is basically a propeller, that propels the water around, is made of a brittle plastic that lasts about 18,000 miles. In the picture above you can see what happens to it. The black circular piece on the left is the impellor and the broken black bits in the middle are what's left of the fins.

A kit can be brought from you local Independent Lotus dealer to replace the impellor and seals, which is low in cost (around £40), but these don't last very long. In the near future I will be doing a guide on replacing this pump with an electric one, which will end the need for this impellor.

How to check if your Chargecooler Pump is working

When the chargecooler pump finally stops working due mainly to impellors failing, it normally goes undetected by the driver as it is gradual. You can loose up to 20 hp on this alone, so you want it to be working. There are a few ways to check if your system isn't working. First is to take the pump off and have a look. Not really the best option, as it involves a lot of work and the pump is hard to get at.

The Service manual recommends the following:

1. Disconnect and plug the outlet hose from the pump.

2. Fit a slave hose to the pump outlet spigot, and place the other end of the hose in a graduated jug of at least 2 litres capacity.

3. Remove the chargecooler header tank cap, or the combined header tank cap as applicable, and prepare at least 2 litres of coolant with which to keep the tank topped up.

4. Start the engine and run at 3,000 rpm, adding coolant as necessary to keep the header tank filled. Time the delivery of 1 litre of coolant into the graduated jug.Specification = 9 - 12 seconds.

This is also a bit involved. For those without mechanical skills, the simpliest way is to take the car on a long enough run to warm the eninge. Then stop the car and open up the engine compartment. Place your hand carefully onto the chargecooler (big red box on the top, with chargecooler on it), this should be cool to the touch, unlike the engine which will be red hot (LEW takes no responsibility for burnt fingers). This must be done quickly, as the chargecooler will suffer from heat soak. If your chargecooler is very hot to touch, then it's likely the system isn't running properly.

Also if you're boost gauge is only getting to half way (0.5 bar) even on a nice cold morning with a warm engine, then one of the reasons may be the chargecooler system isn't working. The engine management system will reduce the boost if the inlet temperatures are too high. All Chargecooled Esprits should over boost to 1 bar and run a transent 0.85 bar, if yours isn't then check the chargecooler first.

The best way to check is to use FreeScan. Look at the MAT values out on the road they will get very high, then pull in and see if the MAT reading falls when the car is idling. If not then the chargecooler pump is not working.

What to do now your pumps isn't working?

There are a few options for those with a faulty chargecooler pump. The worst (in LEW's opinion) is to buy a new one. The pump is only faulty inside, as the Pump's aluminium housing should last the life of the car, so don't spend between £250-350 on a new one, it's money wasted. If you like getting your hands dirty and knuckles scraped, then you can by a service kit (£40+) and replace the impellor yourself. The kits are cheap and it should only take half a day (or so!). LEW's Esprit has had this done, but unfortunately no camera was available, so currently there is no guide, but it will be done at some point.

If you don't fancy it, you can send the pump off to be recon'd for about £100+. But this will involve taking it off, which is the hardest part, so you might as well fix it yourself. A Lotus Specialist should charge around £150 if you take your car to them. This includes labour and new internals.

Personally LEW recommends removing the old mechanical pump and replacing it with an Electric pump. An Electric pump will cost you around £80-100, but should last the life of the Esprit, unlike the original one, which will need the impellor replacing regularly over the life of the car. Also the flow rate will be increased, making the chargecooler more efficient. You will need to blank off the old mounting and wire up the pump to an ignition live. It's not a difficult Job in it's self, but access does make it hard work. LEW will be doing this in the near future, as the pump has been ordered, so look out for a guide.

In the meantime here's a pretty good guide:

www.andywhittaker.com/lotus/electricchargecoolerpump.htm

Here's an artical about Stock vs Electric pumps

www.wcengineering.com/articles/chargecooler.html

Here are some links on where to buy an electric pump:

www.wcengineering.com/esprit/pump.html

John Walschwww.demon-tweeks.co.uk

Demon Tweekshttp://www.thinkauto.com/waterpumps.htm

Think Autohttp://www.johnson-pump.com

Johnsonhttp://www.michaelsmotorsports.com/electricchargecooler.htm

These are the parts needed to block off the old pump:

Sealing Plug A910E2424F

Retaining Plate A910E2425F

'O' Ring A907E6251F

CHARGECOOLER PUMP by Paul Chandler

I found that I was losing coolant from the chargecooler tank, whenever I had lost some coolant I had traces of Emulsified water on the oil dipstick. With this in mind I decided to get an electric chargecooler pump fitted. The unit I used was this one:And PNM engineering made the blanking plug for the old pump position.

Steve Williams fitted the pump for me, and I then took the old one apart to see what kind of condition it was in. I found the impeller had lost all it’s blades, and that the bits of blade had actually blocked the outlet in the pump Housing.

I also found traces of water-oil emulsification in the shaft of the pump, so it appears I was correct in my diagnosis of the coolant loss. But more importantly this action showed that my chargecooler system was not working!

With the Electric unit now fitted, my chargecooler is COLD. Not just cooler than everything else in the engine bay, but genuinely very cold! The car goes a lot better too now, and now I know just how cold the CC should Be, I’ll never let my SE limp around with a defective one again, after all, we are are talking about 30-40 bhp extra…

![]()

|

|